In the digital display industry, the performance of an LED display depends largely on a key component: the LED lamp bead. As the most expensive and widely used component in an LED display, the LED lamp bead plays a dominant role in the quality of the display.

These tiny light-emitting units form the basis of each pixel and directly affect brightness, color accuracy, energy efficiency, and durability.

This article will explore the lamp beads used in LED displays, including their types, technical specifications, and how they affect the performance of LED displays. We will also discuss lamp bead selection criteria, the advantages of high-quality lamp beads, and more.

1. What are LED lamp beads?

What are the lamp beads used in LED displays? LED lamp beads are the basic light-emitting units used in LED screens. Essentially, they are tiny semiconductor devices that efficiently convert electrical energy into visible light.

In LED display technology, LEDs play a crucial role in determining brightness, color accuracy, refresh rate, and overall image quality. They are typically arranged in a red, green, and blue (RGB) color combination to form pixels, creating vivid, dynamic visuals on large screens.

2. History of LED Development

- In 1907, British scientist Henry Joseph Land first discovered electroluminescence in silicon carbide crystals. Although the light was very weak, it marked the beginning of LED research.

- In 1962, Nick Holonyak Jr. of General Electric invented the first visible red LED, opening the door to practical LED applications.

- After the 1990s, with the help of new materials such as gallium nitride, blue LEDs emerged, enabling full-color displays (red, green, and blue). This breakthrough also promoted the application of LEDs in the lighting field, gradually replacing incandescent and fluorescent lamps.

- Today, LEDs are widely used in display and lighting fields, and emerging technologies such as Micro-LEDs and OLEDs continue to expand their performance and application areas.

1. DIP (Dual In-Line Package) LEDs

DIP LEDs are the earliest form factor used in LED displays. They are cylindrical in shape and have two or more pins that plug into the circuit board.

Advantages: High brightness, excellent outdoor visibility, durability, and low cost.

Disadvantages: Large size, limited resolution, and narrow viewing angle.

Applications: Outdoor billboards, traffic signs, and monochrome/dual-color screens.

2.SMD (Surface Mount Device) LEDs

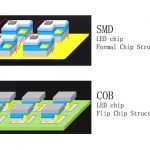

SMD LEDs are compact, lightweight, and soldered directly to the PCB surface. They integrate red, green, and blue chips into a single package, enabling finer pixel pitch and higher resolution.

Common SMD LED models include 1415, 3535, and 5050, with these numbers typically representing the size of the LED (for example, 5050 indicates a width of 5.3mm and a length of 5.3mm).

Advantages: Small size, wide viewing angle, vivid colors, high resolution, and uniform brightness.

Disadvantages: Lower brightness in direct sunlight and less robust than DIP LEDs.

Applications: Indoor LED displays, retail advertising, stage LED backdrops, and fine-pitch screens.

3. COB (Chip-on-Board) LEDs

COB LEDs mount multiple chips directly onto a substrate and cover them with resin. This design improves heat dissipation, reliability, and impact resistance.

Advantages: Excellent heat dissipation, seamless visuals, high durability, and ultra-fine pixel pitch.

Disadvantages: High production costs and difficult repairs (usually requiring module replacement).

Applications: Control rooms, conference rooms, command centers, and high-end fine-pitch displays.

4. How do LED beads affect the performance of LED displays – 8 major factors:

(1) Viewing angle

The viewing angle of an LED display is determined by the viewing angle of the LED beads. At present, most outdoor LED displays use elliptical LEDs with a horizontal viewing angle of 100° and a vertical viewing angle of 50°, while indoor displays use chip LEDs with a horizontal and vertical viewing angle of 120°.

Due to its special nature, circular LEDs with a viewing angle of 30° are generally sufficient for displays on highways.

Some high-rise displays have higher requirements for vertical viewing angles. Viewing angle and brightness are contradictory. A larger viewing angle will inevitably reduce brightness. The choice of viewing angle needs to be determined according to the specific application.

Because LEDs are angular, full-color LED displays also exhibit angular directionality. This means their brightness increases or decreases when viewed from different angles.

Thus, the angular consistency of the red, green, and blue LEDs significantly impacts the consistency of white balance across different angles, directly affecting the color fidelity of the displayed video.

Achieving consistent brightness matching of the red, green, and blue LEDs at varying angles requires careful attention to the LED packaging design and raw material selection, which depends on the technical expertise of the LED lighting supplier.

Poor angular consistency of the LED lamp beads can lead to poor white balance across the entire screen. Therefore, the angular consistency of LED lamp beads can be measured using an LED angle tester, which is particularly important for high-end displays.

The most critical component of a full-color display is the LED lamp beads. They are the most expensive and most used component in an LED display, and they play a dominant role in the quality of the display.

(2) Brightness

LED brightness is an important factor in determining the brightness of the display. The higher the LED brightness, the greater the current margin, which helps save power and maintain the stability of the LED.

LEDs have different angle values. When the chip brightness is constant, the smaller the angle, the brighter the LED, but the viewing angle of the display is also smaller. Generally, a 100-degree LED should be selected to ensure that the display has a sufficient viewing angle.

For displays with different dot pitches and different viewing distances, it is necessary to find a balance between brightness, angle, and price.

(3) Failure rate

Since a full-color display is composed of tens of thousands or even hundreds of thousands of red, green, and blue LEDs, a failure of any one color LED will affect the overall visual effect of the display.

In general, according to industry experience, the failure rate of an LED display from the beginning of assembly to the 72 hours of aging before leaving the factory should not exceed 0.03% (referring to failures caused by the LED lamp beads themselves).

(4) Antistatic Capability

LEDs are semiconductor devices that are sensitive to static electricity and are prone to static failure. Therefore, antistatic capability is crucial to the life of the display.

Generally speaking, the failure voltage of the human body static mode test for LEDs should be no less than 2000V.

(5) LED display lifespan

The theoretical lifespan of LED devices is 100,000 hours, which is much longer than the working lifespan of other components of the LED display.

Therefore, as long as the quality of the LED device is guaranteed, the operating current is appropriate, the PCB heat dissipation design is reasonable, and the display production process is rigorous, the LED device will be one of the most durable components of the entire display.

(6) Attenuation characteristics

LED lamp beads can account for 70% of the price of LED display screens, so the quality of LED lamp beads directly determines the quality of LED display screens. China is not only a major producer of LED devices, but also a gathering place for LED display screen manufacturing. The high technical requirements of LED display screens are the future development trend.

The requirement for higher quality of LED display screens is not only related to the trend of LED display screen manufacturers, but also to the development of LED display equipment manufacturers. From the control of LED equipment, it will promote China’s transformation from a major LED display screen manufacturing country to a strong LED display screen manufacturing country.

After working for a long time, LED display screens will experience brightness reduction and inconsistent display colors. This is mainly caused by the brightness attenuation of LED devices. The attenuation of LED brightness will reduce the brightness of the entire screen.

The inconsistent brightness attenuation of red, green and blue LEDs will cause inconsistent color of LED display screens, which is what we often call the phenomenon of display screen flower.

High-quality LEDs have well-controlled brightness decay. Based on the standard of operating at 20mA for 1000 hours at room temperature, red brightness decay should be less than 2%, and blue and green brightness decay should be less than 10%. Therefore, when designing displays, it’s not advisable to use a 20mA current for blue and green LEDs; it’s best to use only 70% to 80% of the rated current.

Degradation characteristics are not only dependent on the properties of the red, green, and blue LEDs, but also on the current used, the PCB heat dissipation design, and the ambient temperature of the display.

(7) Size

The size of LED lamp beads affects the pixel pitch of LED display screens, that is, the resolution. 5mm elliptical lamps are mainly used for outdoor displays above P16, 3mm elliptical lamps are mainly used for outdoor displays of P12.5, P12, and P10, and 3528 chip LEDs are mainly used for indoor displays of P6 and P8.

2020 SMD LEDs are mainly used for indoor displays such as P2 and P3.

Under the premise of keeping the pixel pitch unchanged, the size of LED devices can be increased, which can increase the display area and reduce the graininess, but the contrast will be reduced due to the reduction of black area.

On the contrary, if the size of LED lamp beads is reduced, the display area will be reduced, the graininess will increase accordingly, and the black area will be expanded, thereby improving the contrast.

(8) Consistency

A full-color display screen is composed of countless red, green, and blue LEDs. The brightness and wavelength consistency of each color LED determines the brightness consistency, white balance consistency, and chromaticity consistency of the entire display screen.

In general, display screen manufacturers require device suppliers to provide LEDs with a wavelength range of less than 5nm and a brightness range of less than 1:1.3. Suppliers can achieve these indicators through spectrometers. There is generally no requirement for voltage consistency.

Since LEDs have angles, full-color LED displays also have angle directionality, that is, their brightness will increase or decrease when viewed from different angles. In this way, the angle consistency of red, green, and blue LEDs will seriously affect the consistency of white balance at different angles, and directly affect the fidelity of the video color of the display screen.

To achieve the matching consistency of the brightness changes of red, green, and blue LEDs at different angles, strict scientific design is required in terms of packaging lens design, raw material selection, etc., which depends on the technical level of the packaging supplier.

No matter how good the reverse white balance is, if the LED angle consistency is not good, the white balance effect of the entire screen at different angles will be poor.

The angle consistency characteristics of LED lamp beads can be measured by an LED angle comprehensive tester, which is especially important for mid-to-high-end displays.

5. LED Beads vs. LEDs (Light Emitting Diodes)

Although the terms LED bead and LED (light emitting diode) are often used interchangeably, they refer to slightly different concepts in LED display technology.

LEDs (light-emitting diodes) are basic semiconductor devices that emit light when an electric current passes through them. They are essential components of electronic products, with applications ranging from small indicator lights to large lighting fixtures.

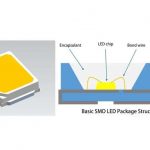

LED lamp beads are packaged and processed versions of LEDs, designed specifically for LED display applications. LED lamp beads integrate one or more LED chips, a package, electrodes, and sometimes a lens or diffuser.

Why choose LED lamp beads for LED displays?

The most basic LED (light-emitting diode) is the core light-emitting component, but for LED displays, LED lamp beads are a higher-quality and more practical choice. Here are the reasons:

●Optimized packaging: Unlike bare LED chips, LED lamp beads are encapsulated with protective material to protect them from moisture, dust, and physical damage.

●Stable performance: The lamp beads integrate electrical connections and optical design to ensure consistent brightness, color accuracy, and long-term reliability.

●Display-oriented design: The LED lamp beads feature a pixel-pitch design, suitable for high-resolution indoor screens as well as large outdoor electronic LED billboards.

●Durability and long life: The encapsulation process enhances heat dissipation and resistance to environmental stress, extending the lifespan of the display.

●Anti-static capability: LEDs are sensitive to static electricity, which can cause failure. High-quality LED lamp beads have strong anti-static protection, reducing the risk of damage and improving overall stability.

●Excellent visual experience: The lamp beads offer uniform brightness and wide viewing angles, providing a superior visual experience compared to raw LED components.

Understanding why LEDs are the preferred light source highlights their critical role in display performance. The next step is to understand how to choose the right LEDs for your LED display to ensure the optimal balance between brightness, durability, and visual quality.

6. How do I choose the right LEDs for my LED display?

Choosing the right LEDs for your LED display is crucial for achieving high-quality visuals, long-term reliability, and cost-effectiveness. The following practical tips can help you make the best choice:

● Consider pixel pitch

Pixel pitch determines the distance between individual LEDs.

Smaller pixel pitches require high-precision SMD or COB LEDs to achieve fine resolution, while larger pixel pitches can use DIP LEDs for bright outdoor displays.

● Check chip quality

LED chips are a core component that determines brightness, stability, heat dissipation, and other factors.

High-quality chips provide consistent illumination, minimize power loss, and ensure long-term performance.

● Check solder joints and surface cleanliness

Reliable LEDs utilize a reflow soldering SMT process, resulting in clean, well-formed solder joints.

Surfaces should be free of dust, stains, or impurities to ensure uniform illumination and prevent color distortion.

● Evaluate glue, encapsulation, and packaging techniques

Durable glue or resin prevents deformation and protects the chip.

Advanced packaging ensures uniform color, consistent brightness, and a wide viewing angle, supported by sophisticated machinery and quality control.

● Evaluate color consistency

Beads should maintain stable red, green, and blue performance across all pixels.

Poor-quality products may exhibit black spots, uneven hues, or noticeable color deviations.

● Consider Viewing Angle and Application

A wide viewing angle is crucial for displays aimed at large audiences or in unusual viewing positions.

Match the lamp type to the environment: DIP for rugged outdoor use, SMD for versatile indoor screens, and COB for ultra-fine-pitch applications.

● Brand Selection and Reliability

Choose a reputable brand with proven performance and certifications, such as NationStar or other trusted suppliers.

Reliable brands offer consistent quality, reduce the risk of failure, and provide long-term technical support.

● Cost and Lifespan Factors

High-quality lamps may have a higher upfront cost, but can reduce maintenance, energy consumption, and downtime.

By carefully evaluating these factors: pixel pitch, chip quality, soldering, surface cleanliness, packaging, color consistency, viewing angle, and brand reputation, you can select LED lamps that deliver vivid visuals, reliable performance, and lasting value.

How to identify high-quality LED display lamps? Quick inspection!

First, check the solder joints. Reputable LED light strip manufacturers use the SMT (Surface Mount Technology) process, using solder paste and reflow soldering.

Second, check the quality of the FPC. FPCs come in two types: rolled copper and copper foil. The copper foil protrudes from the copper plate, and if you look closely, you can see it at the connection between the solder pads and the FPC.

Third, check the surface cleanliness of the LED strip. LED strips produced using the SMT process will have excellent surface cleanliness, with few impurities or stains visible.

Fourth, check the LED chip and production process. These cannot be seen with the naked eye; use aging equipment and testing equipment.

If you place LEDs from several manufacturers in a aging tester and use high current for 24 hours or longer, then measure the brightness of these LEDs, you can see which LED has the least luminous intensity loss. The LED with the least loss is considered the highest quality.

7. Recommended Top Chinese LED Display Light Manufacturers

When sourcing high-quality LED display light beads, choosing a reliable manufacturer is crucial for performance, lifespan, and overall cost-effectiveness. Below, we highlight the top five Chinese LED display light bead manufacturers:

① Superior Brightness and Clarity:

High-quality lamp beads deliver strong luminous intensity with low power consumption. They ensure clear, vivid images in any environment, including direct sunlight for outdoor displays.

② Excellent Color Consistency and Accuracy:

Advanced manufacturing ensures uniform performance across red, green, and blue chips.

Displays show smooth gradients, accurate tones, and vibrant visuals.

③ Enhanced Longevity and Durability:

Premium LED lamp beads use high-quality materials and advanced encapsulation techniques.

They offer better heat dissipation, moisture resistance, and impact protection, reducing dead pixels and dimming.

④ Wide Viewing Angles and Stable Performance:

Images remain consistent when viewed from different angles or distances.

This is critical for stadium screens, stage backgrounds, and large public displays.

⑤ Lower Total Cost of Ownership:

Although initial investment may be higher, high-quality lamp beads reduce maintenance needs and energy consumption.

Their long lifespan provides a better return on investment over time.

In conclusion, choosing high-quality LED display lamp beads ensures outstanding display performance, reliability, and cost efficiency, making them essential for professional LED display solutions.